Solutions for high level exterior decorative material demands.

Sunmento Cera EXE/EXL are exterior decorative parts made of "calcium silicate based ceramic material" that have been autoclaved under high temperature and pressure conditions. EXE products, recently released in May 2018, have great strength and excellent workability. The major feature of EXM/EXL products is that it can be customized to meet various needs such as taper/groove and radius processing, as well as customizing its size and shape. Mainly, Sunmento exterior products are perfect for face and workpiece material in a wide variety of ways and can be used for exterior on public facilities or commercial buildings that require safety and security.

Ad Frame (casing).

Decoration on the "doors" at the entrance.

Exterior decoration of the "eaves" at the entrance.

Main Features of Sunmento Cera EXE/EXL

- There is no deterioration, corrosion and insect damage because it is made of mineral-based molded plate.

- There is no toxicity because the constituent substances do not contain asbestos.

- You can freely cut, carve or drill a hole, among other options.

- Sealer is applied before shipping from the factory, so the parts can be installed immediately onsite after arrival.

Sunmento Cera EXE/EXL Specifications

| Usage | [ For Exterior ] Molding, Parting material, Columns | |

| Material | CSC: Calcium silicate based ceramic material Certified incombustible products: <EXE>NM-2204 <EXL>NM-2607 |

|

| Surface finishing | Non-painted product (Sealer is applied before shipping from the factory) | |

| Lead-time | Made to order product | |

| Formaldehyde Regulation | Exempt product from formaldehyde regulation. Exempt product from formaldehyde notification. |

Usage

[ For Exterior ] Molding, Parting material, Columns

Material

CSC: Calcium silicate based ceramic material

Certified incombustible products: <EXE>NM-2204 <EXL>NM-2607

Certified incombustible products: <EXE>NM-2204 <EXL>NM-2607

Surface finishing

Non-painted product (Sealer is applied before shipping from the factory)

Lead-time

Made to order product

Formaldehyde Regulation

Exempt product from formaldehyde regulation.

Exempt product from formaldehyde notification.

Exempt product from formaldehyde notification.

Certified incombustible products: NM-2204

Physical Data of Sunmento Cera EXE

| Item | Stats | Measuring method | ||

|---|---|---|---|---|

| Density | 1.1±0.1 | JIS-A5430 | ||

| Bending strength | 7.8Mpa or over | JIS-A1408 | ||

| Moisture content | 20% or less | JIS-A5414 | ||

| Water absorption rate | 45% or less | JIS-A5430 | ||

| Moisture dimensional change ratio | 0.12% or less | JIS-A5430 | ||

| Freeze-thaw durability | 300 cycles without abnormality | ASTM-C666B method |

Density

1.1±0.1 (Measuring method: JIS-A5430)

Bending strength

7.8Mpa or over (Measuring method: JIS-A1408)

Moisture content

20% or less (Measuring method: JIS-A5414)

Water absorption rate

45% or less (Measuring method: JIS-A5430)

Moisture dimensional change ratio

0.12% or less (Measuring method: JIS-A5430)

Freeze-thaw durability

300 cycles without abnormality

ASTM-C666B method

ASTM-C666B method

Certified incombustible products: NM-2607

Physical Data of Sunmento Cera EXL

| Item | Stats | Measuring method | ||

|---|---|---|---|---|

| Density | 0.85±0.1 | JIS-A5430 | ||

| Bending strength | 4.9Mpa or over | JIS-A1408 | ||

| Moisture content | 25% or less | JIS-A5414 | ||

| Water absorption rate | 60% or less | JIS-A5430 | ||

| Moisture dimensional change ratio | 0.2% or less | JIS-A5430 | ||

| Freeze-thaw durability | 300 cycles without abnormality | (ASTM-C666B method) |

Density

0.85±0.1 (Measuring method: JIS-A5430)

Bending strength

4.9Mpa or over (Measuring method: JIS-A1408)

Moisture content

25% or less (Measuring method: JIS-A5414)

Water absorption rate

60% or less (Measuring method: JIS-A5430)

Moisture dimensional change ratio

0.2% or less (Measuring method: JIS-A5430)

Freeze-thaw durability

300 cycles without abnormality

(ASTM-C666B method)

(ASTM-C666B method)

Packaging and delivery fees charged separately

To prevent damage during shipping, Sunmento Cera products will require additional packaging and delivery fees. We will provide quotation for shipping or air-shipping costs upon receiving order quantity.

Sunmento Cera EXE/EXL Recommended adhesive agent

- Epoxy resin adhesive

List of tools for Sunmento EXE/EXL

| Work process | Tools | |

|---|---|---|

| Cutting | Chip saw, diamond saw, etc. | |

| Point hole | Concreate core drill, etc. | |

| Seat boring, punching (drilling) | Concrete drill, hole saw, etc. | |

| Polishing (repair) | Grinder, belt sander, sandpaper, etc. | |

| Bolts, screws, etc. (examples) | Anchors for RC and ALC, tapping screws, etc. |

Cutting

Chip saw, diamond saw, etc.

Point hole

Concreate core drill, etc.

Seat boring, punching (drilling)

Concrete drill, hole saw, etc.

Polishing (repair)

Grinder, belt sander, sandpaper, etc.

Bolts, screws, etc. (examples)

Anchors for RC and ALC, tapping screws, etc.

[ Customization ] available for Sunmento Cera EXL

- We accept your choice of design, shape and size that are not listed.

- Before placing a custom order, please review the following check-list for preferred specs.

| Usage | Parapet border / border (decorative beam) / decorative column / jamb Before placing a custom order, please review the following check-list for preferred specs. |

|

| Customized Shapes | Add changes to ready-made products (Example 1) Different shape from ready-made products (Example 2) (1) Tapering available (2) Grooving available Radium processing on ready-made molding pieces (Example 3) |

|

| Sizes | Moldings: Height x Depth x Length / Diameter (outer dimension) | |

| Material | CSC: Calcium silicate based ceramic material | |

| Painting | Delivered as non-painted parts (sealer applied) | |

| Order Lots | Orders from 1 piece available | |

| Pricings/Lead-time | Prices and delivery times vary depending on the shape and quantity, so we will provide a quotation and lead-time for each order individually. Depending on the shape, a "blade cost" for processing may be applied separately. |

|

| Request for technical drawings | Please send us technical drawing with specs and dimensions for each part when ordering to prevent mis-ordering and for minimum lead-time by achieving mutual understanding. |

Usage

Parapet border / border (decorative beam)/decorative column/jamb

Gable, eaves, exterior wall decoration, window head, window casing, door casing, ribbed panels.

Gable, eaves, exterior wall decoration, window head, window casing, door casing, ribbed panels.

Customized Shapes

Add changes to ready-made products (Example 1)

Different shape from ready-made products (Example 2)

(1) Tapering available

(2) Grooving available

Radium processing on ready-made molding pieces (Example 3)

Different shape from ready-made products (Example 2)

(1) Tapering available

(2) Grooving available

Radium processing on ready-made molding pieces (Example 3)

Sizes

Moldings: Height x Depth x Length / Diameter (outer dimension)

Material

CSC: Calcium silicate based ceramic material

Painting

Delivered as non-painted parts (sealer applied)

Order Lots

Orders from 1 piece available

Pricings/Lead-time

Prices and delivery times vary depending on the shape and quantity, so we will provide a quotation and lead-time for each order individually.

Depending on the shape, a "blade cost" for processing may be applied separately.

Depending on the shape, a "blade cost" for processing may be applied separately.

Request for technical drawings

Please send us technical drawing with specs and dimensions for each part when ordering to prevent mis-ordering and for minimum lead-time by achieving mutual understanding.

Sunmento Cera EXL [ Custom Order ] Examples

Caution on Product Selection & Installation for Sunmento Cera EXE/EXL

- Sunmento Cera EXE/EXL(for exterior) shall not be used untreated. Please make sure to coat the material with waterproof paint for exterior finishing. Particularly in cold climates, please coat with waterproof paint that protects from frost damage.

*Please re-apply coating/paint within the expiration date of the original coat.

*For places where severe deterioration is expected, apply coating in advance. - Installation can be performed by using a combination of special screws, adhesives, and anchors specifically designed for the jointing surface.

- Sealer is applied before shipping from the factory, so adhesive agents may be applied directly.

*1. When using a sealer, be sure to use a permeable polyurethane resin based or epoxy sealants and. (Do not use the film formation type.)

*2. If you are installing it on-site, make sure to check sawdust and dust are not on the jointing surfaces, and make sure to reprocess the sealer.

*3. After making sure that sawdust and dust is not collected in the pits or small holes, make sure to apply the sealer and fill it in with epoxy putty and perform repairing, etc.

*4. If the products have been stored for a long period of time, be sure to reprocess the sealer before using. - Please apply paint/coating on Sunmento Cera EXE/EXL after applying osmotic sealant.

*5. Please follow directions provided by the manufacture of the used paint/coating for appropriate application and methods.

*6. Do not paint on Sunmento Cera that has absorbed water or moisture due to rain after installation. Please dry it thoroughly and then apply paint. - In case of major damage, replace with new parts since it can cause water to penetrate.

- For repairing small damage, remove dust and dirt from the surface, apply a permeable sealer, and use an epoxy-type putty to repair within 2 days after drying.

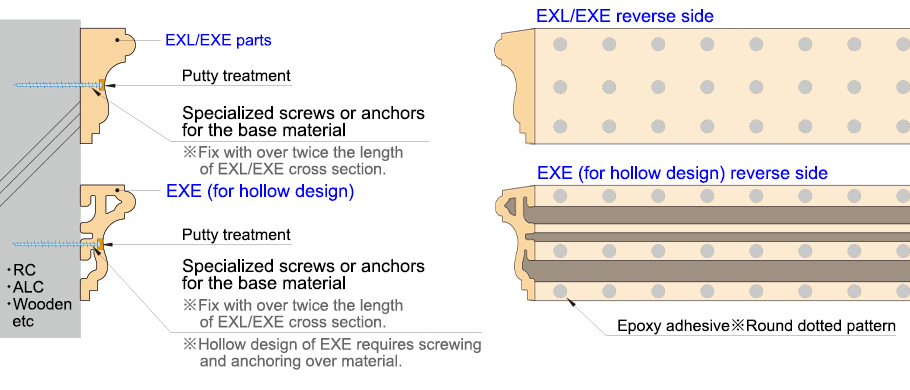

- Please apply the epoxy adhesive in dotted pattern with consistent intervals on the bonding surface to the outer wall on the reverse side of the product.

*7. Since the base material has a tendency to shrink, sealing is recommended for the jointing area. - Tapering in advance is recommended to prevent water collection on top and flowing to the back side. (Available only on EXE) Please review the above mentioned "Custom Order Examples" for details before inquiring.

*8. When using in cold climates, be sure to provide adequate draining (tapering and grooves). (Available only on EXE)

*9. When using the product in cold regions, please refer to the following coating measures and consult with the paint manufacturer for appropriate coating in advance.

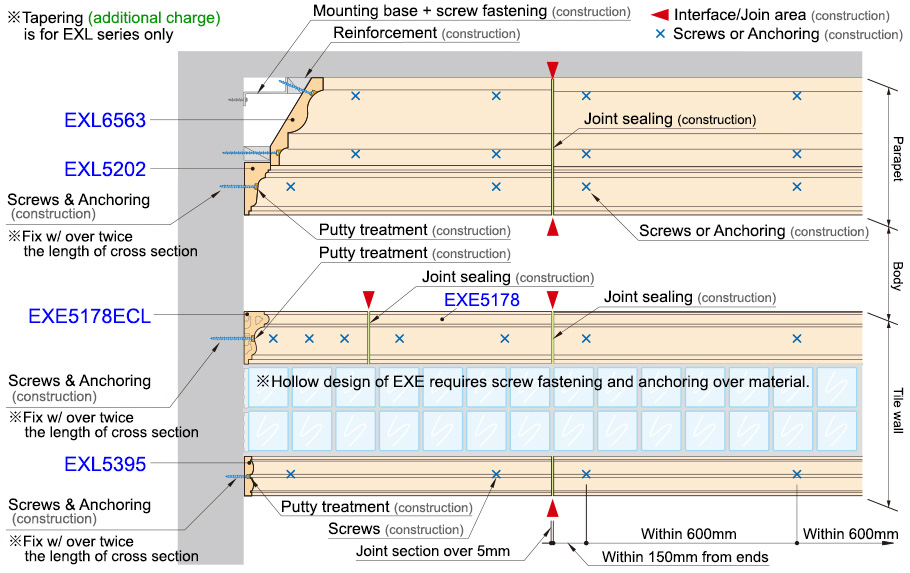

Referential Detailed drawing (Screws or anchoring examples)

Installation schematic for exterior wall

Before installation, please check the mounting area and consult specialized manufacturers to select appropriate screws or anchors, putty, epoxy adhesive, etc.

Cold region coating measures (Common to Sunmento Cera EXE/EXL)

1. Environmental Conditions

2. Typical defective phenomenon with coating

3. Selection of primer

4. Selection of top coat

- Avoid painting/coating during rain, snowfall, frosting or strong winds.

- Avoid painting under the environment of 5 Celsius or less and above 85RH% humidity (Favorable range is between 15-30 degrees temperature and 40-75 RH% humidity)

- Avoid painting if the object is ph10 or more and moisture content 8% or more.

- Low temperature will slow drying process and increase susceptibility to the adverse effects of moisture, such as dust and condensation. In addition, the viscosity of the paint increases which causes the workability to decline.

- With high temperature, drying becomes faster, and with two-component paints, expiration date becomes shorter. If the temperature of the object is 50 degrees or higher under the sun, you may want to avoid painting as it may cause bubbling.

- With high humidity, condensation is likely to occur, and if the paint is applied to the dewed surface, it may cause peeling, or if moisture is mixed in the paint, it may cause repelling. In addition, due to the surface temperature drop from the solvent evaporation, moisture in the air may condense on the surface of the coating to cause a whitening phenomenon.

- Condensation occurs when the relationship between temperature, humidity, and surface meets dew point conditions, so it is critical to predict condensation by measuring these factors even during coating process.

- When rain, snow or frost affect the coating before it is sufficiently dried, the paint may be washed away, crater-like irregularities may appear, or the gloss may be reduced as well as cause whitening.

- Strong wind will cause the paint to scatter and contaminate the environment, or dust and sea salt particles will fly and stick to the undried layer, which is not preferable.

- If the adhesive viscosity cannot be obtained even with the "Retan I. O. Sealer" currently used, apply "Multi-tile concrete primer EPO" (2-component epoxy resin primer) on-site.

- "Multi-tile concrete primer EPO" is an epoxy resin primer containing gray colored pigment and is excellent in adhesion because it impregnates the material and forms a primer coat.

- Because drying time for overlay painting requires 23 degrees for 16 hours or more and within 7 days, when painting in the cold, allow about 3 days of drying time for thorough drying.

- We recommend solvent paints that are more volatile than water-based paints in cold climates. Our recommendations are the following paints that are fast drying.

- Low polluting ceramic modified terpene soluble urethane resin paint ... "Cera M Retan"

- Low polluting ceramic modified terpene soluble acrylic silicone resin paint ... "Cera M Silicone II"

© 2019 MIHASHI Co.,ltd.